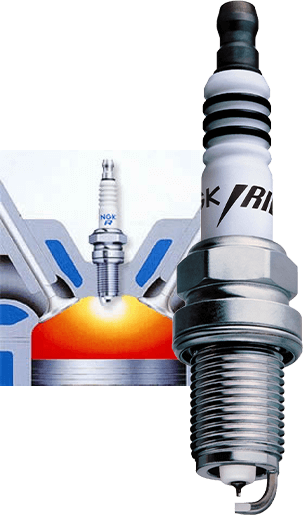

NGK Spark Plugs

NGK have over 80 years of experience in spark plug manufacturing and we are a world leader in spark plug technology. We have an extensive range of spark plugs, each with their own unique characteristics specifically engineered to its vehicle application and they are designed to suit a broad range of vehicles on Australian roads. With our dedication to quality, outstanding reliability and state of the art manufacturing techniques, you can rely on NGK Spark Plugs.

Don’t just ask for a spark plug, insist on NGK.

What is a spark plug and what does it do?

An internal combustion engine requires three key ingredients to operate: air, fuel and spark. A spark plug is a critical engine component that provides the spark that ignites the air-fuel mixture that drives an engine.

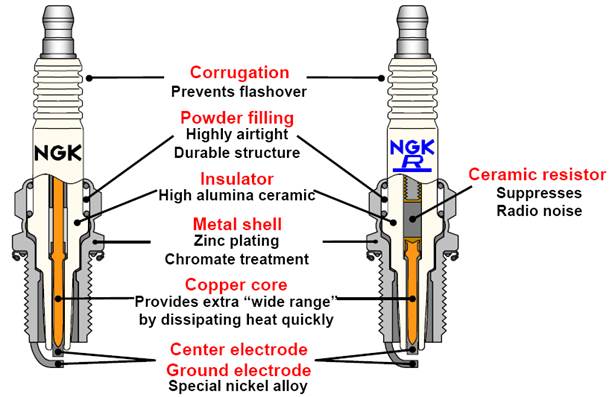

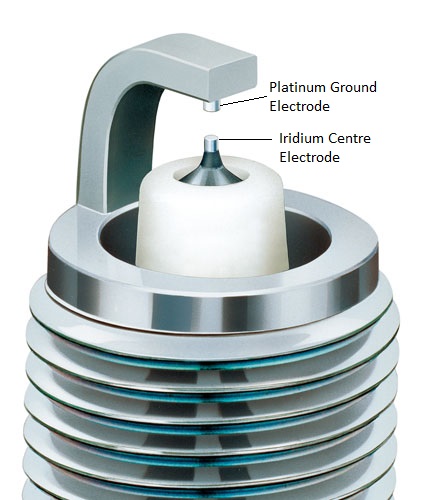

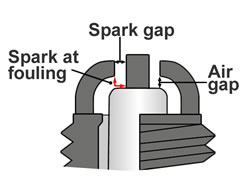

A spark plug operates by directing electrical current to flow through a centre electrode, forming a spark across an electrode (or air) gap, completing the circuit to a ground electrode. The centre electrode is surrounded by a ceramic insulator which is non-conductive preventing current leakage and ensuring electricity flows in the desired direction.

Anatomy & Construction

Although the spark plug is a familiar engine component, spark plug terminology often varies. This diagram identifies the major components of a spark plug and their correct terminology.

Details

Centre Electrode

Nickel

Ground Electrode

Nickel

Service Life **

20,000 – 40,000km

Benefits

Standard style Spark Plug

*NGK Spark Plugs are designed to OEM requirements and as such, a variant of each of the above styles may not be available as it may not be an OEM requirement.

**Please note that the service life is provided as a general guide and may vary due to vehicle driving conditions.

Details

Centre Electrode

Nickel

Ground Electrode

Nickel

Service Life **

20,000 – 40,000km

Benefits

Improved ignitability due to sparking at periphery of the electrode

*NGK Spark Plugs are designed to OEM requirements and as such, a variant of each of the above styles may not be available as it may not be an OEM requirement.

**Please note that the service life is provided as a general guide and may vary due to vehicle driving conditions.

Details

Centre Electrode

Iridium tip

Ground Electrode

Nickel

Service Life **

60,000km

Benefits

Long service life and even better ignitability due to a small diameter centre electrode

*NGK Spark Plugs are designed to OEM requirements and as such, a variant of each of the above styles may not be available as it may not be an OEM requirement.

**Please note that the service life is provided as a general guide and may vary due to vehicle driving conditions.

Details

Centre Electrode

Platinum tip

Ground Electrode

Platinum pad/chip

Service Life **

100,000km

Benefits

Extremely long service life. High ignitability due to fine tipped centre electrode

*NGK Laser Series Spark Plugs are designed to OEM requirements and as such, a variant of each of the above styles may not be available as it is not an OEM requirement and product attributes may vary from what is detailed above.

**Please note that the service life is provided as a general guide and may vary due to vehicle driving conditions.

Details

Centre Electrode

Iridium tip

Ground Electrode

Platinum pad/chip

Service Life **

100,000km

Benefits

Extremely long service life. Improved high ignitability due to fine tipped centre electrode.

*NGK Laser Series Spark Plugs are designed to OEM requirements and as such, a variant of each of the above styles may not be available as it is not an OEM requirement and product attributes may vary from what is detailed above.

**Please note that the service life is provided as a general guide and may vary due to vehicle driving conditions.

Details

Centre Electrode

Iridium tip

Ground Electrode

Platinum tip

Service Life **

100,000km

Benefits

Superior ignitability due to fine tip centre and ground electrodes. Excellent service life.

*NGK Spark Plugs are designed to OEM requirements and as such, a variant of each of the above styles may not be available as it may not be an OEM requirement.

**Please note that the service life is provided as a general guide and may vary due to vehicle driving conditions.

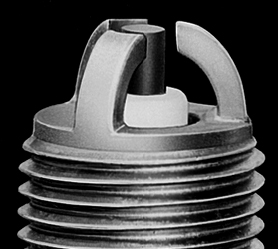

Surface Discharge Spark Plug

A surface discharge spark plug is designed to create a spark along the insulator nose at the firing end. This type of spark plug can be further classified into the semi-surface discharge type, supplementary gap type and intermittent discharge type.

Features:

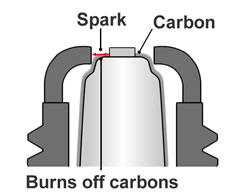

Semi-surface discharge type

The wide gap of semi-surface discharge type improves ignition capability and is less sensitive to voltage requirement increases due to gap growth. Semi-surface discharge plugs burn away the carbon on the insulator nose to suppress a decline of insulator resistance.

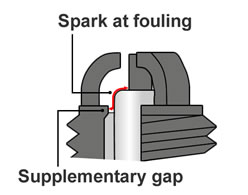

Supplementary gap type

Spark discharge at the supplementary gap burns away the carbon on the insulator to suppress a decline of insulation resistance. The small clearance between the insulator supplementary gap prevents the carbon-included combustion gasses from entering the gas volume. This reduces the carbon accumulation on the insulator.

Intermittent discharge type

Spark discharge at intermittent gaps burn away the carbon on the insulator to suppress a decline of insulation resistance.

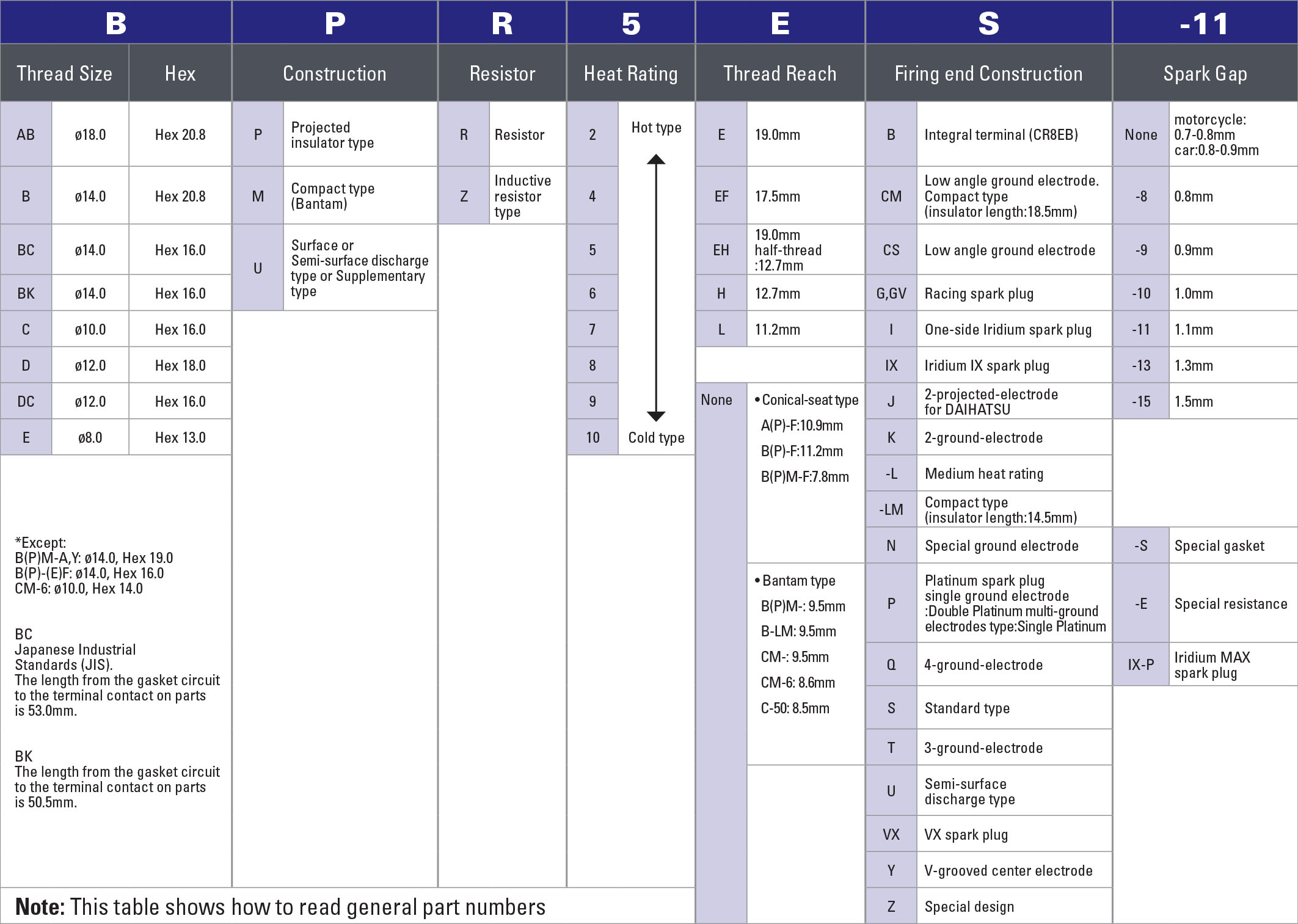

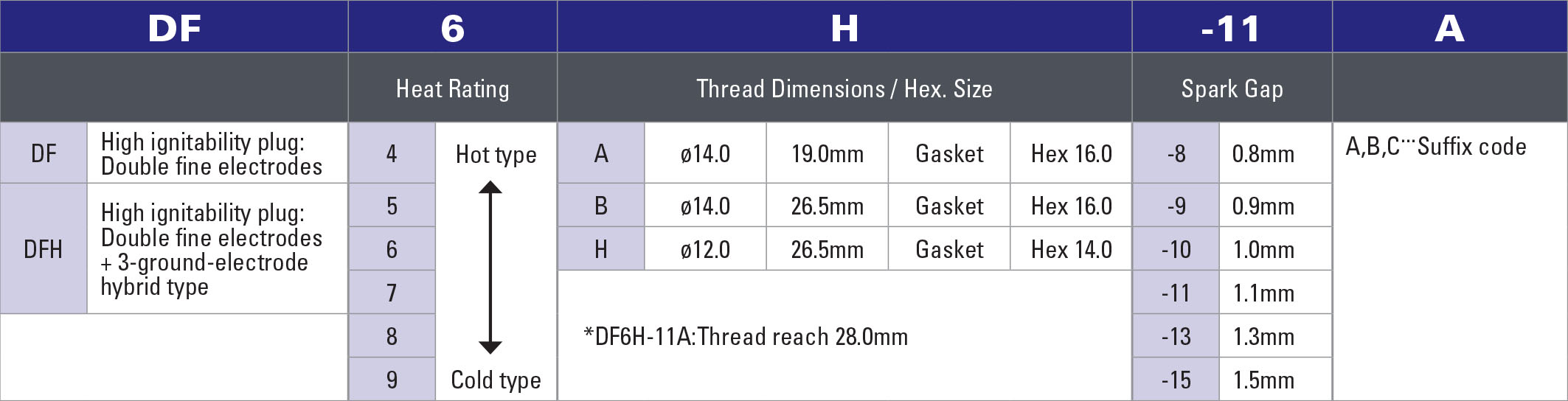

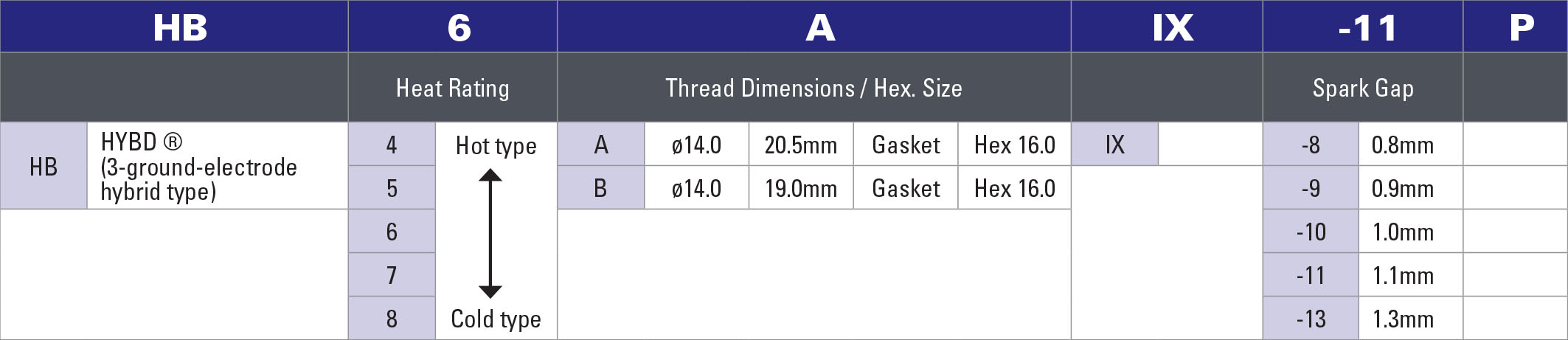

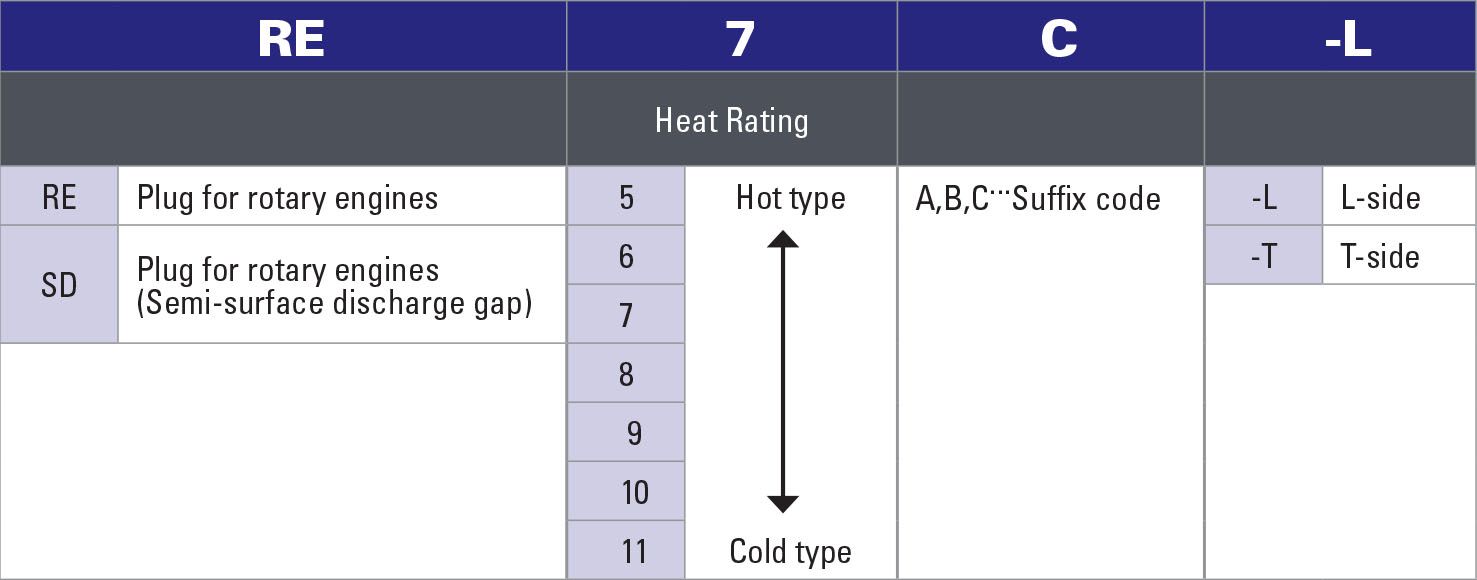

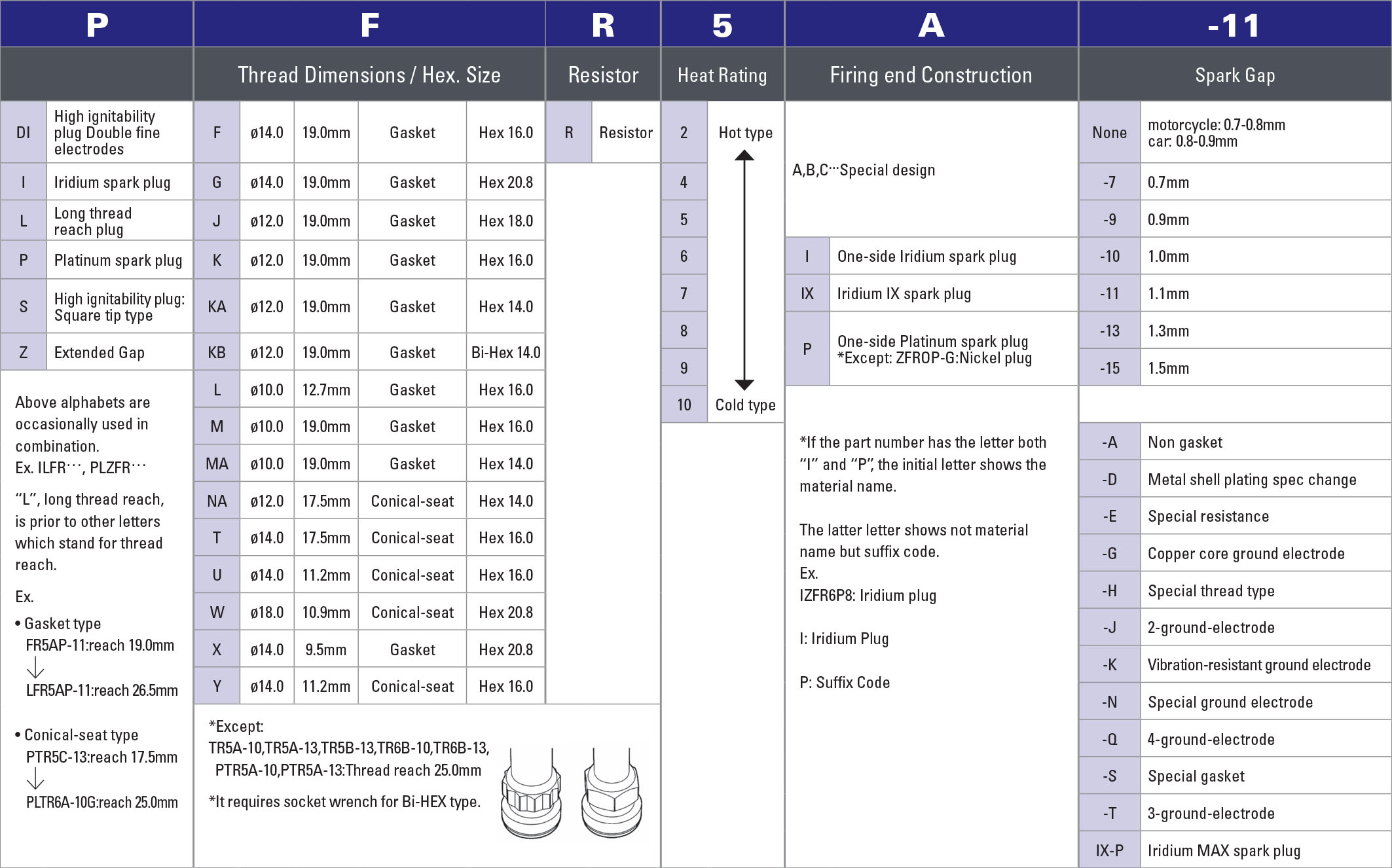

Part Numbering System