NTK position sensors play vital roles in the function of vehicles, communicating the position of various components to the computer for safe, efficient driving.

Engine Camshaft Position Sensors report camshaft rotation timing and speed, a vital component of ignition system and vehicle computer communication.

Purpose

The engine camshaft sensor determines the exact position and speed of the camshaft(s) to ensure proper timing of fuel injection and ignition as well as VVT operation

Function

NTK camshaft position sensors are available in either analog (inductive principle) or digital (hall effect) technologies. The two technologies are not interchangeable.

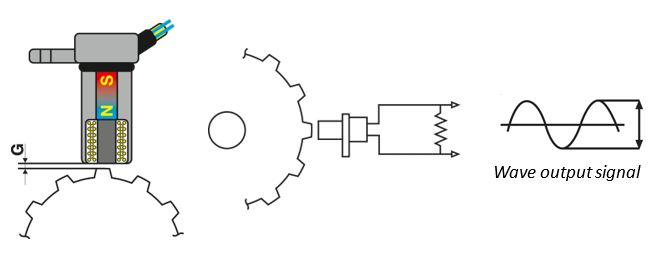

- Analogue (Inductive) Sensor

- Generates a signal, no external power supply

- Wave-form output signal

- Only signal when camshaft turns

- Voltage rises with camshaft speed, and depends on distance to camshaft (“G“)

- 2 or 3 Pins (3rd for shield)

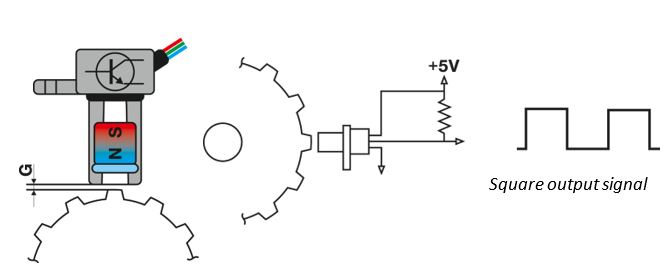

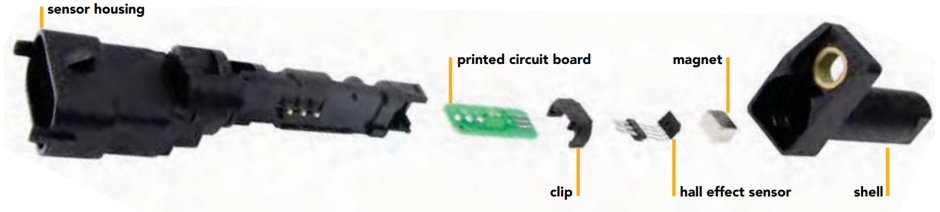

Digital (Hall Effect) Sensor

- Integrated electronics

- External power supply of 5V

- Square output signal (0V/5V)

- Can detect a position even if the camshaft is at a standstill

- 3 Pins

Position

Located in the cylinder head, valve cover or timing cover

Cause for replacement

- Check engine lamp illumination

- No start

- Hard start/extended cranking time

- Failed emissions test

- Engine misfire

The NTK Difference

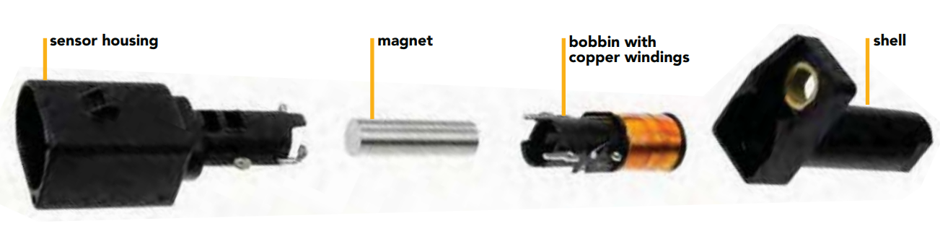

- More robust circuit board design to increase durability

- Precision-wound, coated-copper windings to increase longevity

- Magnet size and strength optimized for precise signal output

- Robotically soldered circuit board connections to increase reliability

- 100% thermo-shock and vibration tested to ensure the best performance in extreme conditions