There are three basic types of EGR valves. Pneumatic EGR valves have a vacuum controlled diaphragm. These valves can enable a higher flow rate that is required by newer diesel applications. Electric EGR valves are controlled through integrated electronics. These valves are run directly by the engine’s control unit and can be much more precisely regulated. And then there are electric EGR valves that have a cooling unit to further reduce the temperature of the exhaust gases.

The new range has the same high quality like all the other products that Niterra are renowned for. To ensure this, all our valve types have undergone and passed testing carried out in extreme conditions. This includes thermal shock testing in temperatures ranging from -40°C to 150°C, tests on valve, cavity and cooling leakage, as well as electrical resistance and lifecycle.

Principles

Nitrogen oxides (NOx) are produced during the combustion process. NOx is created when high combustion temperatures enable the nitrogen and oxygen present in the air-fuel mixture to combine. To reduce these harmful emissions the EGR valve takes exhaust gases from the exhaust manifold and reintroduces them into the intake manifold, mixing them with fresh air. This has a double effect, reducing the amount of oxygen in the air-fuel mixture and reducing the temperature, and thereby reducing the amount of NOx the engine produces.

Function

EGR stands for ‘exhaust gas recirculation’. An EGR valve performs the role of reducing NOx emissions. NOx is produced during the combustion process. It is created when high combustion temperatures enable the nitrogen and oxygen present in the air-fuel mixture to combine. To reduce these harmful emissions, the EGR valve takes exhaust gases from the exhaust manifold and reintroduces them into the intake manifold, mixing them with fresh air. This has a double effect, reducing the amount of oxygen in the air-fuel mixture and reducing the temperature, and thereby reducing the amount of NOx the engine produces.

Position

The EGR valve is located beside or on top of the engine, close to the intake manifold. It has a tube which leads to the exhaust manifold.

Cause for Replacement

A defective EGR valve is not automatically a major problem but if it is not replaced, it can cause issues over time. These include the particle filter becoming damaged. In addition, deposits can also form within the intake manifold and the intake valves can become coated and gummed, which can lead to damage to the turbocharger, a loss of power or even the engine stopping.

The NTK Difference

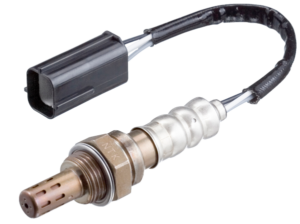

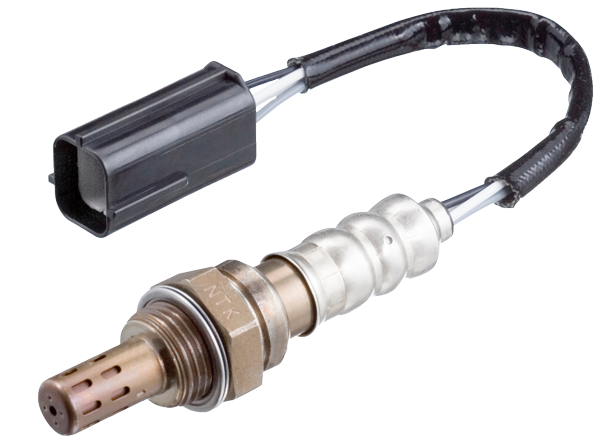

Rigorously tested for quality and performance, NTK sensors are engineered to meet or exceed OE specifications.

- Dual aluminum wire bonding ensures a more reliable and longer lasting product

- Patented microcontroller technology design for more accurate temperature compensation

- A laser cut, ceramic cylinder, glass-coated sensor with platinum film increases the accuracy under different airflows and temperatures

- Available with full housing or a probe only option for easier installation depending on the application